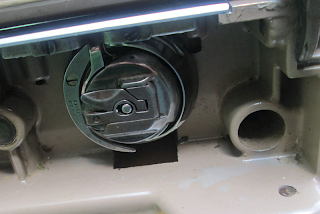

This is a White Rotary treadle. There are about four different colored threads wrapped around these posts in the shuttle race assembly. It took several minutes to pick all these threads out. I still can't figure out how so many different colored threads got wound around in there.

I needed to relax with some mindless work today. I chose to clean this machine. There is a new definition of grime in my book. I was able to get the machine turning nicely. I sprayed tri flow every where I could. No motor to worry about and the cosmetics are shot so now I am focused on getting it stitching.

Then I had a call from a friend who has a friend who needs a machine. So I serviced an eBay purchase a nice little Kenmore 12 stitch

I love this machine. It is lightweight. It sews very nicely and it has a built in button holer. I love the smocking stitch. I made the drawstring bag and decided to stitch out an example of every stitch on the bag. Cute idea, even if I do say so myself.

I think this may be a keeper. I am not sure why. I have the Keatherweight for classes should I need to haul a zz machine. But I may want to build an inventory of my own machines, should I ever teach classes myself.

Or maybe I will just sell it.

The machine is very clean inside. Too bad the seller did such a poor job packing it. The machine sustained only minor damage to the extension table and spool pins. The case, on the other hand was significantly damaged.

I had emailed him/her and asked that the machine be wrapped in bubble wrap inside the case as well as outside. Stupid me. The machine arrived in a box with one sheet of bubble wrap next to the cased up machine. It wasn't even enough to wrap all the way around the machine. Fortunately I had some money refunded so that helped. Stupid idiot moron.

A blog devoted to my vintage sewing machines and how I find them, fetch them and fix them.

Wednesday, May 30, 2012

Saturday, May 26, 2012

Why it wouldn't stitch

Those of us who love to sew and who know about sewing machines understand the importance of the needle. I am always amazed that people who complain that their machine doesn't work haven't changed the needles since "I don't know.." when.

I think that this needle came from a newer machine that Betsy and I were struggling to time. I wish that the happy ending was that all it took was a new needle. Not so. We gave up and decided that we just had to use it as a parts machine. So far, it has given me two tension discs. And a bobbin case. So there. Worth the ten bucks we gave for the machine.

I think that this needle came from a newer machine that Betsy and I were struggling to time. I wish that the happy ending was that all it took was a new needle. Not so. We gave up and decided that we just had to use it as a parts machine. So far, it has given me two tension discs. And a bobbin case. So there. Worth the ten bucks we gave for the machine.

How to pack a Sewing Machine for Shipping.

I love these machines so much. When I pack them, I pack to be sure that they arrive safely.

Notice that the spool pin on top is missing. It is tucked safely in the bag in a little baggie with the bobbins. I just realized that I did leave the light bulb in the machine. But I think it should be ok.

I start with making sure that the take up lever is down and that the presser foot is down. Then I wrap them up with bubble wrap and secure with painters tape. Painters tape is easier to take off and it doesn't mar the finish. (OK so now [May 28, 2012] I have learned from a very nice reader that in her experience IT DOES mar the finish....see comments below. DARN) I wrapped the little bag of goodies up and secured it to the bed of the machine as well.

I slit a cork and then wrapped tape around it. That way it would be tight enough to sit on the bobbin winder spool pin. I stuffed packing material between the cork and the machine so that should something hit the cork it would not give way into the machine.

Next I wrapped the stitch length lever with bubble wrap and secured it in place. The white stuff is polyester fill that came with a machine I bought on eBay.

I was going to wrap the machine with the batting but I don't have the cool saran wrap stuff to snug it all down next to the machine. So I stuffed some in the bed and wrapped the whole machine with bubble wrap. LOTS OF IT. I used a fair amount of tape to secure the bubble wrap.

And then I put this in a box with padding all around it. I actually triple boxed this machine. The inner box was a double box that came with the machine packed in the batting. It was a snug fit and I wanted to be sure that there was extra cushioning. I put that box into another and stuffed plastic grocery bags all around the inner box to make it a tight fit.

Sorry no pictures of boxes. What's the point?

It shipped today. I know it will travel today and tomorrow. Max is traveling east today and tomorrow. This machine is traveling west. I wonder if their paths will cross?

Notice that the spool pin on top is missing. It is tucked safely in the bag in a little baggie with the bobbins. I just realized that I did leave the light bulb in the machine. But I think it should be ok.

I start with making sure that the take up lever is down and that the presser foot is down. Then I wrap them up with bubble wrap and secure with painters tape. Painters tape is easier to take off and it doesn't mar the finish. (OK so now [May 28, 2012] I have learned from a very nice reader that in her experience IT DOES mar the finish....see comments below. DARN) I wrapped the little bag of goodies up and secured it to the bed of the machine as well.

I slit a cork and then wrapped tape around it. That way it would be tight enough to sit on the bobbin winder spool pin. I stuffed packing material between the cork and the machine so that should something hit the cork it would not give way into the machine.

Next I wrapped the stitch length lever with bubble wrap and secured it in place. The white stuff is polyester fill that came with a machine I bought on eBay.

I was going to wrap the machine with the batting but I don't have the cool saran wrap stuff to snug it all down next to the machine. So I stuffed some in the bed and wrapped the whole machine with bubble wrap. LOTS OF IT. I used a fair amount of tape to secure the bubble wrap.

And then I put this in a box with padding all around it. I actually triple boxed this machine. The inner box was a double box that came with the machine packed in the batting. It was a snug fit and I wanted to be sure that there was extra cushioning. I put that box into another and stuffed plastic grocery bags all around the inner box to make it a tight fit.

Sorry no pictures of boxes. What's the point?

It shipped today. I know it will travel today and tomorrow. Max is traveling east today and tomorrow. This machine is traveling west. I wonder if their paths will cross?

Singer 301

SOLD

I really must "thin the heard" as it is called. I have a 301 Mocha Long Bed. I don't need a Short Bed, too. So this one is elected. The hook had a burr on it so I switched the hook from my LBOW to this one. It sews very smoothly and the motor is fine. I featured this machine on an earlier post http://mysewingmachineobsession.blogspot.com/2011/11/train-whistle.html.

I cleaned the old grease off of the gears. I used Tri-Flow grease as the lubricant. It works very well and doesn't spray all over. It Sticks.

I cleaned the textolite gear on the handwheel. I used NO SOLVENTS on this gear. It is a fibre gear and I did not want anything to absorb into its 60 plus year innards. I wiped it wipe a cloth and the, using a pick from a nut cracker set, scraped the old grease out of each crevice VERY GENTLY.

I pulled the motor and cleaned the worm too. I admit, I did not scrub the inside of the machine here. Ray claims that is for cosmetic purposes only. I agree.

I was just cruising eBay (I can't help it) there is a 301 someone is trying to sell as "pristine" with black gunk all over the gears. YECH. I prefer gears with metal showing and just a hint of moisture from the Tri Flow.

I hate to see it go, but go it must. Such is the way of the sewing machine fanatic. Until I become a hoarder, some of them just have to come for a bit, get cleaned up and stitching and then move on.

Tuesday, May 22, 2012

DONT TRY THIS AT HOME

Betty, from Maine, sent me another photo. This one was of the wire to her 201 motor.

Frankly this frightened me and I emailed her right away to never turn that machine on again and to check out the post on Rain's blog. http://vssmb.blogspot.com/2012/01/complete-how-to-re-wire-potted-motor.html

Who knows what that wiring is like inside? I had a machine that had BEAUTIFUL wiring on the outside but the re-wire at the field coil was so bad that I was surprised I didn't electrocute myself when I bought the machine.

Actually I would love to look at this motor. I am sure that the wires need to be replaced all the way to the field coil. But Betty can do it. I am sure she can.

Frankly this frightened me and I emailed her right away to never turn that machine on again and to check out the post on Rain's blog. http://vssmb.blogspot.com/2012/01/complete-how-to-re-wire-potted-motor.html

Who knows what that wiring is like inside? I had a machine that had BEAUTIFUL wiring on the outside but the re-wire at the field coil was so bad that I was surprised I didn't electrocute myself when I bought the machine.

Actually I would love to look at this motor. I am sure that the wires need to be replaced all the way to the field coil. But Betty can do it. I am sure she can.

SHE DID IT !!!!!

Here it is folks, Betty's 221 motor. She did it all by herself. Isn't she clever? This all started with an email that she sent me with a couple of photos.

If I had been using my Dell Laptop then, instead of my MacBook Pro I would have been able to save and enlarge the photo and probably have been able to see that her concern was over the thicker insulation on the two wires.

Well, she did it she got her motor off and was able to figure out what the heck that was. Of course, hind sight is always 20/20 vision. I learned something and she did too. She learned that she can take a motor off of a Feather weight. Ain't this hobby The Best?

If I had been using my Dell Laptop then, instead of my MacBook Pro I would have been able to save and enlarge the photo and probably have been able to see that her concern was over the thicker insulation on the two wires.

Well, she did it she got her motor off and was able to figure out what the heck that was. Of course, hind sight is always 20/20 vision. I learned something and she did too. She learned that she can take a motor off of a Feather weight. Ain't this hobby The Best?

Monday, May 21, 2012

This one is for Betty. Singer 221 Motor

I had an email from a very nice lady in Maine about her Featherweight. She had some questions about the wires to the motor. I suggested that she take the motor off to inspect the wires. I assured her she could do it and promised that I would post photos of how I did this tonight. Here they are.

First I took off the bottom by unscrewing the thumb nut

This revealed the bottom and the wires. Whoa this bottom is wet. Guess I had better clean it up some. Clearly I used too much oil. Good thing I am doing this.....I have circled the motor wires clamp. I loosened this.

I released the motor from the base of the machine first thing. But I think that you could wait and do that last. It flopped around a bit when I was messing with the wires on the bottom of the machine. I unscrewed the motor position screw all the way and removed the motor from the machine

And then put that screw right back in its hole on the motor.

I then freed up Mr Three Pin Terminal

And released the motor wires from it. The nuts on the back of Mr. TPT did not release all that easily by hand. I gently loosened them with a pair of small pliers wrapped in leather. The motor is connected to terminals 2 and 3. The red lead goes to #3. You can almost see the red thread in the cloth cover of the motor lead here. Almost. And oh my, I guess that is glue holding Mr. TPT together, now isn't it? Oh the things you learn about the machine. I wonder how that broke?

Once the leads were released from Mr. TPT, I put him back in place. I hate losing parts. I did remove the motor clamp completely at this point and stretched the motor leads out gently.

Then I gently maneuvered the leads through the hole in the base of the machine. I pulled one through at a time. Since #2 is slightly shorter, this worked out ok. I was VERY gentle. I did not want to hurt these 60 year old wires.

I put the motor wire clamp back in its place and put the bottom back on the machine. I did check one of the brushes. It looks ok. But peering into the brush holder I could see that the commutator is kind of dirty.

I guess I can service it on Wednesday. The #2 motor lead has some exposed wire on its end. I think that is ok since it doesn't touch anything else on Mr TPT. When I put the thing back together I will double check.

This whole operation took me less than 30 minutes. I am not an expert. This is simply how I got the motor off of this machine. I realize, as well, that this post is very similar to a previous post. But I wanted to go through this process, step by step for Betty, in Maine. She is up there trying to figure these machines out solo. I, at least, have Betsy and had the chance to take the Ray White class. So any help I can offer, I am glad to.

First I took off the bottom by unscrewing the thumb nut

This revealed the bottom and the wires. Whoa this bottom is wet. Guess I had better clean it up some. Clearly I used too much oil. Good thing I am doing this.....I have circled the motor wires clamp. I loosened this.

I released the motor from the base of the machine first thing. But I think that you could wait and do that last. It flopped around a bit when I was messing with the wires on the bottom of the machine. I unscrewed the motor position screw all the way and removed the motor from the machine

I then freed up Mr Three Pin Terminal

And released the motor wires from it. The nuts on the back of Mr. TPT did not release all that easily by hand. I gently loosened them with a pair of small pliers wrapped in leather. The motor is connected to terminals 2 and 3. The red lead goes to #3. You can almost see the red thread in the cloth cover of the motor lead here. Almost. And oh my, I guess that is glue holding Mr. TPT together, now isn't it? Oh the things you learn about the machine. I wonder how that broke?

Once the leads were released from Mr. TPT, I put him back in place. I hate losing parts. I did remove the motor clamp completely at this point and stretched the motor leads out gently.

Then I gently maneuvered the leads through the hole in the base of the machine. I pulled one through at a time. Since #2 is slightly shorter, this worked out ok. I was VERY gentle. I did not want to hurt these 60 year old wires.

I put the motor wire clamp back in its place and put the bottom back on the machine. I did check one of the brushes. It looks ok. But peering into the brush holder I could see that the commutator is kind of dirty.

I guess I can service it on Wednesday. The #2 motor lead has some exposed wire on its end. I think that is ok since it doesn't touch anything else on Mr TPT. When I put the thing back together I will double check.

This whole operation took me less than 30 minutes. I am not an expert. This is simply how I got the motor off of this machine. I realize, as well, that this post is very similar to a previous post. But I wanted to go through this process, step by step for Betty, in Maine. She is up there trying to figure these machines out solo. I, at least, have Betsy and had the chance to take the Ray White class. So any help I can offer, I am glad to.

Wednesday, May 16, 2012

Our Walk

We live on top of the Utica and Marcellus Shale. Supposedly the source of enough natural gas to supply the country with "clean" energy for generations. The problem is that in order to retrieve this abundance, the shale must be "fractured" and the process, known as High Volume Horizontal Hydraulic Fracturing, is bad for the planet. The fluid is loaded with carcinogens as well as hormone disrupters and the process disturbs radon and millions years old bacteria that come back up with the flow back. Not to mention that it requires MILLIONS of gallons of water that will never be clean EVER AGAIN. It is terrifying. Our government thinks that this can be done safely. It cannot. Norway and Quebec have banned it. France did too. However, this process has been used in the US and the devastation it has wrought on the air and water and people's lives is irreparable. Some of our neighbors have leases. Our only hope is a state wide ban. We are working toward. that. In the meantime, I am driving less, the furnace is now off for the season, and we are looking in to better ways to insulate our one hundred year old home.

Monday, May 14, 2012

Japanese zz continued

Voila. Very nice stitches. I think this satin stitch is almost as nice as the one on the 237. I guess I didn't know how nice they were.

Saturday, May 12, 2012

Zigging and Zagging on a treadle

I have been determined to try to fit one of my zz machines in the treadle stand that Steven and I built last winter. Because Betsy and I had another demo Saturday at the Farmer's Market, I had a deadline. I took the motor off of the Japanese no name machine and rasped down the edges of the opening in the stand so it would fit. I had to shorten the belt as well. It worked great.......It is so wonderful to be able to zig zag with a treadle. Lots of folks really enjoyed our demo and we had several people, including some kids, trying it out. Some were naturals. Others had more of a challenge. It was a fun day and I love treadling with my Japanese Zig Zag. I think the 237 can treadle as well....

Thursday, May 10, 2012

Singer 237 vs Kenmore 158.96

I love this machine

I also love this machine

But for different reasons

The Kenmore is strong and quiet and it makes decorative stitches with cams.

The 237 makes a beautiful satin stitch but it is not as strong as the Kenmore. It is quiet, but not as smooth sounding.

If I had to choose between the two, I would choose the Kenmore; hands down. It can zig zag and I could live with its satin stitch. I think. I guess I should check it out. Still, sewing on the Kenmore is a much more pleasing experience. I am happy when I am sewing on it.

But for different reasons

The Kenmore is strong and quiet and it makes decorative stitches with cams.

The 237 makes a beautiful satin stitch but it is not as strong as the Kenmore. It is quiet, but not as smooth sounding.

If I had to choose between the two, I would choose the Kenmore; hands down. It can zig zag and I could live with its satin stitch. I think. I guess I should check it out. Still, sewing on the Kenmore is a much more pleasing experience. I am happy when I am sewing on it.

Monday, May 7, 2012

Out of Control AGAIN

I just had to have a 237. When one came up on CL I called and asked the seller to save it for me. No worries. I was the only caller. That explains why no one ever buys my machines I list on Craigs list

Steve went with me to fetch this. It was an interesting transaction. The seller wanted to meet at a public place . I chose Starbucks. Then I realized we would need an outlet to try the machine out. I scouted out Starbucks when Steve and I arrived (and after I bought a coffee). No outlets accessible.

I phoned the seller to let him know we were at Starbucks and mentioned the lack of available outlets. He still did not invite us over. He suggested Brueger's Bagels. So we walked across the parking lot and searched for electricity. We found one outlet, but heck, now we had to buy something else. Luckily we like bagels.

There is something about fetching a sewing machine in a public place. It is just plain odd. I guess people are afraid to allow strangers in their homes. Funny, the woman from whom I bought the 328 an hour previously was not worried at all. She invited me in, we went to the garage, we chatted about wonderful old used things, especially sewing machines. It was great.

So at the Bagel shop I looked over this machine. The case is in terrible shape and the machine almost fell out as the seller lugged it in. I checked out the tension assembly. The tension release plate/ tension indicator is plastic and can break. It was broken. Still I did not argue over the price. Someone else may have. I have this thing about promising to buy something and then dickering over the price. I don't think its right.

But the tension indicator part (which in this machine doubles as the tension release plate) was not the only broken tension part. The screw nut was also cracked.

I have no idea if the machine will work like this or not. I will do my best to find a replacement. I went up to Ithaca last Wednesday for another repair class. I worked on a 237 there with these same issues. The teacher, Toby Benetti, just handed me new parts. He's a professional, he has them on hand. Had I known that I was going to get this machine then, I would have bought a couple of sets of these from him. It is possible to buy a completely new tension assembly but why should I when all I need is the screw nut? Maybe Toby will sell me one. He sure was a nice guy at class.

UPDATE

In response to Rain's question/comment I tried a tension assembly from a 66 that I had kicking around. The check spring on the 15-91 is totally different and I have no spare 201 tension assemblies. The tension stud is shorter

So I kept the original and just used the metal tension release plate/+/- indicator and the numbered dial.

It seems to work. I did have some issues tweaking it and I think it needs more tweaking. But I am happy with the stitch

Of course looking at it now, it isn't so pretty. When I look at it in real time, it is.....

The shop

This is my work bench. I love to look at it and see the very beautiful sewing machine that came back to life this weekend.

Vintage White 167

Steven and I went to Albany yesterday to fetch a Singer 328K and a Singer 237. On the way home we hit a thrift shop in Cobleskill. There were three machines for sale. A Kenmore 120 something. A newer model Singer and a mystery machine in a "desk." There were things on top of the "desk" so I asked permission to see it. The very nice lady told me that it didn't work. I insisted on seeing it, which set her aback a bit. I could tell. The machine had no tension assembly, only the tension stud and check spring were intact. It was dirty but it did turn over. I asked if I could buy the machine only and she said "You can take them out?" So I gave her a little lesson in sewing machine set screws.

I oiled it first thing when I got it home. The stitch length knob WOULD NOT MOVE. I applied heat and got it to budge a little. I pulled the motor out and sprayed Tri flow and put the machine on its side so that the solvent could seep down into the stitch length knob. Then I left it alone and went to work on the 237.

Sunday I finished up the Stylist. It does make a gorgeous satin stitch. I can't wait to sew with it.

Then I set to work on this machine. It was a challenge. On that long bed 301 you could see all the sticky"varnish" from congealed oil. Not on this White. It took most of the day to just get the stitch length knob freed up. The zz mechanism was stuck too. It does have plastic cam for built in decorative stitches. I cleaned them up the best that I could. Now they could be nylon. But I don't know how to tell. Look like plastic to me.

Finally I was able to put my attention to the tension mess. I had found some parts in the drawer at the shop. I salvaged them when I took the machine. But the stop was missing and two of the tension discs were gone. I had one (it is a twin needle machine so would have three discs) but that isn't enough. The tension release pin was also missing.

I managed to cobble together a tension assembly form various assemblies I had available. This is a hybrid White Singer assembly. I learned the concept of tension assembly and what each part does from Toby Benetti last Wednesday. Thanks to that lesson I was able to piece together a functioning tension assembly. And the machine stitches.

The knob is from a 306W I bought at an auction with Betsy last fall. I didn't realize it was a parts machine then. Good thing I had it, though.

The numbered dial is from a tension assembly Betsy salvaged from one of her Singers. We had used a tiny little set screw from one of my Singers to fix a 401 of hers. She brought me the whole tension assembly to replace that set screw.

The stop came from the same assembly.

The beehive spring was original to the machine. I found it in the drawer of the "desk"

The tension release plate indicator was also original to this machine.

The tension discs were from a later model White that bit the dust when we tried to re-time it. I don't think we even noticed that it did not have a check spring!!!

The check spring came from a Singer 66

The tension stud was original. I used the tension release pin from the Singer assembly.

I had the original check spring as well, but I buggered it up when I was trying to get the tension stud out. I released the set screw but that was holding the whole silver jacket in place. Once I got that out I found the set screw that was holding the check spring in place.

It isn't gorgeous like the original tension assembly was. BUT it works. Maybe one day I will find a very cool looking one for this machine....

The machine is not really sure of itself in the straight stitch mode. There is a bit of a list......I know that it has to do with lubrication. It is just a question of working it and getting things moving again. I hope that the automatic button holer works. I love the way this machine sounds. It is very quiet and smooth. Fit and Finish. That is what these machines are all about.

UPDATE November 16, 2013

A reader wrote asking how to set the machine in straight stitch mode. Hers is set is zz mode now Here is a photo with directions.

Loosen Stitch width selector lock 1. Move stitch width selector 2 all the way to zero. Set needle position selector, 3, to M . Set stitch selector (4) to Zig zag. When the width is set to 0, there will be no zz. At least that is the way I think it is supposed to be set. That's what worked for me. Be sure that the machine is well lubricated and all parts move easily before attempting to move anything. Don't force it.

Subscribe to:

Posts (Atom)